Understanding Custom Urethane Hardness: A Guide to Durometer Measurement

Welcome to Weaver Industries, your premier destination for custom urethane solutions tailored to your unique needs. With a diverse range of applications spanning from mallets to food processing equipment to textiles, we specialize in crafting high-quality urethane products that meet the exacting demands of various industries. Central to the performance and functionality of our urethane creations is the crucial aspect of hardness, measured by a device known as a durometer.

What is Urethane Hardness?

Urethane hardness refers to the resistance of urethane materials to indentation or penetration by a harder object. This property is of paramount importance as it directly influences the performance, durability, and suitability of urethane products for specific applications. Understanding urethane hardness is essential for selecting the right material for your needs.

The Durometer Scale

The durometer is the standard measurement tool used to quantify the hardness of elastomeric materials such as urethane. It involves a simple test where a calibrated instrument is pressed against the surface of the material to measure its resistance to indentation.

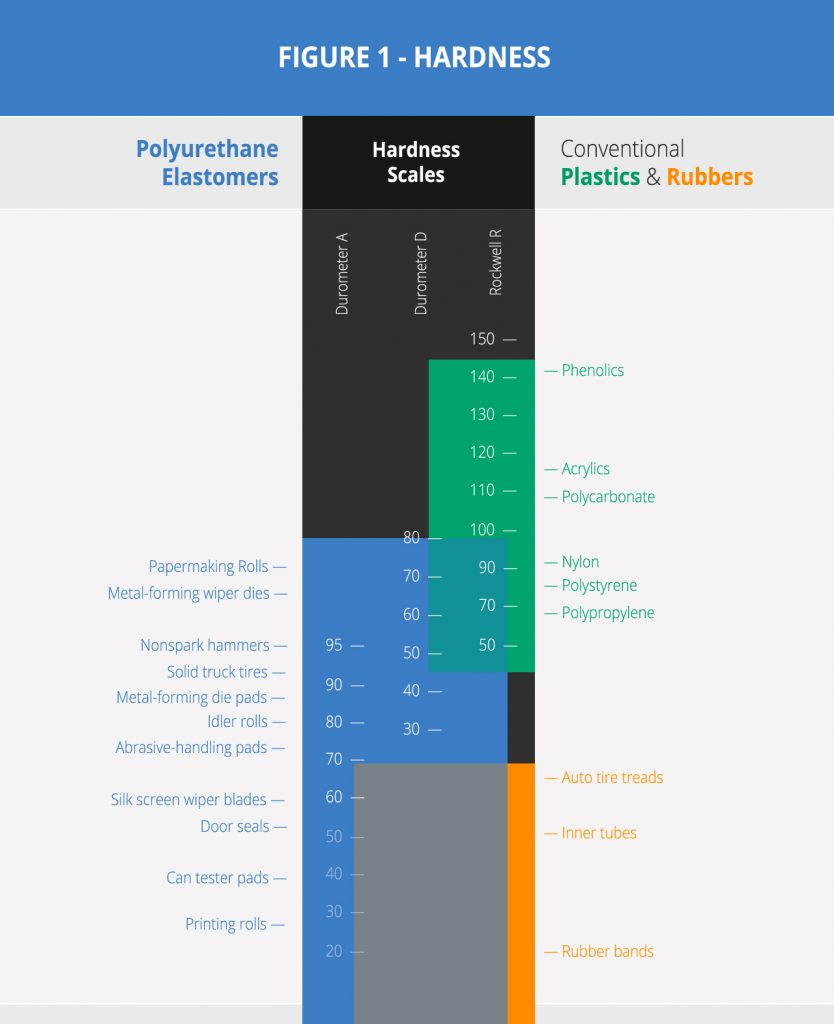

From 30 Shore “A” (soft) to 80 Shore “D” (hard). Please reference the Hardness Chart for more information and to compare hardness across products and materials. We have the capacity to develop customized urethane by creating new formulations or by adapting basic formulas to exact specifications, ensuring accurate shape, weight, size, color and hardness of the products to suit your needs.

Varying Hardness Grades

At Weaver Industries, we offer a spectrum of urethane hardness grades to accommodate diverse requirements and applications. Here’s an overview of some common hardness grades and their respective characteristics:

Soft Urethane (Low Durometer)

Soft urethane, characterized by low durometer readings, exhibits high flexibility and resilience. It has excellent shock absorption properties, making it ideal for applications where impact resistance and cushioning are crucial. Common applications include:

- Mallets and Hammer Faces: Soft urethane mallets provide gentle yet effective impact without damaging delicate surfaces.

- Bumpers and Padding: Used in machinery and equipment to absorb shocks and reduce vibration.

- Textile Machinery Components: Soft urethane rollers and guides ensure smooth handling of delicate fabrics.

Medium Urethane (Moderate Durometer)

Medium hardness urethane strikes a balance between flexibility and rigidity, offering versatility across a wide range of applications. It provides adequate durability and abrasion resistance while retaining some level of elasticity. Examples of applications include:

- Food Processing Equipment: Medium hardness urethane components are used in conveyor belts, scraper blades, and seals to withstand wear and tear in food processing environments.

- Industrial Rollers and Wheels: Suitable for conveyor systems, printing presses, and material handling equipment.

- Seals and Gaskets: Provides effective sealing in hydraulic and pneumatic systems.

Hard Urethane (High Durometer)

Hard urethane, with high durometer readings, possesses exceptional hardness, rigidity, and resistance to deformation. It is favored for applications requiring superior load-bearing capacity, abrasion resistance, and dimensional stability. Key applications include:

- Mining and Construction Equipment: Hard urethane components endure harsh conditions, such as abrasive materials and heavy loads, in mining and construction machinery.

- Oil and Gas Seals: Resistant to chemicals, oils, and extreme temperatures, making them suitable for seals and gaskets in oil and gas exploration.

- Metal Forming Dies: Hard urethane is used to create durable and precise forming dies for metal fabrication processes.

Custom Solutions for Your Needs

At Weaver Industries, we understand that each project has unique requirements. That’s why we offer custom urethane formulations tailored to your specific hardness, performance, and application needs. Our experienced team works closely with clients to develop bespoke solutions that deliver optimal results and exceed expectations. Contact us today to discuss your requirements and discover how our custom urethane solutions can elevate your operations.